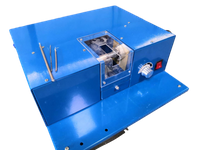

1. Key description

| Pause | Power indicator lamp |

| Manual/Automatic | Manual on the left and automatic on the right. |

| Manual/Cutting | Motor start switch, stop on the left, start on the right |

| Pause | Power switch |

| Backward | Move forward manually, press the material forward in manual state, use when loading the line |

| Forward | Manually retreat, press the material back in the manual state, use when retracting |

| Cutting | Manually cut off, press the material in the motor starting state to cut off the material, and cut the wire manually before cutting it. |

The data on the control panel can be adjusted according to the actual.

2.Counter setting method

Turn on the power, LED display, press zero, press RST to reset.

Press SET to enter the parameter settings LED display.

Press ENT again until you return to the boot interface - complete

3.Cold end length adjustment

Cold end length adjustment screw twist--Lengthened cold end length

Cold end length adjustment screw twist out--Shorten the cold end length

4.Depth adjustment of groove

Cold end depth cutting adjustment screw twist--Shallow cold end depth Cold end depth cutting adjustment screw twist out--Deepen the depth of the cold end

5. Instruction

Turn on the power supply -- connect the compressed gas (barometer shows 3kgs).--Set the required length, change the appropriate mold, threading, set the number, length, speed, slot depth, cold end length, then twist manual/cutting to the right - twist manual/automatic to the right and the device starts working. Then turn manual / automation to the left, manual / cutting to the left, and press Pause to switch the device to stop.

6. Function

Automatically straighten the armor line, rotary cutting and stripping head length 15mm, the length error is 1mm, armour diameter is 2.6~6mm, total length is not limited. Total quantity can be set to complete automatic shutdown.