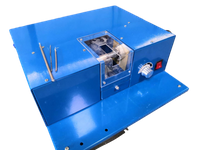

Efficient deep hole drilling machine

Introduction:

High-efficiency deep hold drilling machine is our factory mechanical and electrical integration, and gun drilling engineering and technical personnel in the absorption of domestic and foreign-related technology, military technology, based on the use of foreign components independently developed some of the deep-hole processing equipment.

Equipment is mainly used in machinery, instruments, electrical equipment, mold manufacturing industry, deep processing of blind holes. Single and multi-axis devices have more kinds of patterns. 500mm~3000mm depth of several series, the processing aperture 2mm~12mm, can meet a variety of manufacturing needs.

CNC driven equipment can be achieved high-precision, high efficiency processing.

Compared to overseas, the local price of comparable models 1/10, energy consumption of similar models for 1/3, while the machining accuracy can compare with that.

Specification and technical data

Number of drilling spindle | 1 | Coolant pump motor | 3000W |

Range of drilling inner dia | 2-12mm | Coolant pump pressure | 7MPa |

Depth of drilling | 1700mm | Pump output | 20L/min |

Forward backward travel | 1850mm | Coolant tank capacity | 600L |

Main motor | 750W | NC system | Nanjing xingqiang |

Longitudinal motor | 1100W | Net weight | 3t |

Workpiece driven motor | 550W | Floor space | 4200mm*520mm |

Spindle speed | 0~3000 | Power rating | 5400W |